With the engine tucked away in Building 28 at the Museum, the cleaning process began. Where to start? We discussed the options and decided that the best route was to work on getting the engine to rotate if possible and do a comprehensive cleaning without disassembling major components.

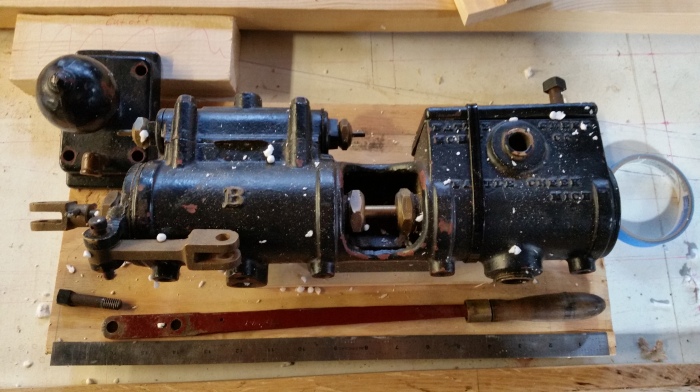

I decided to start at the bottom primarily because that area (crankshaft, camshaft, connecting rods etc.) was the dirtiest and key to getting it to rotate.

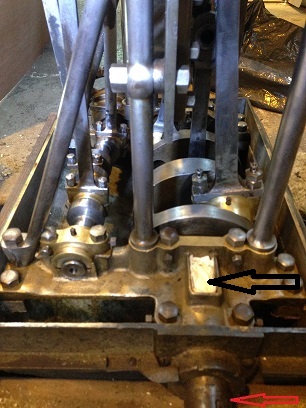

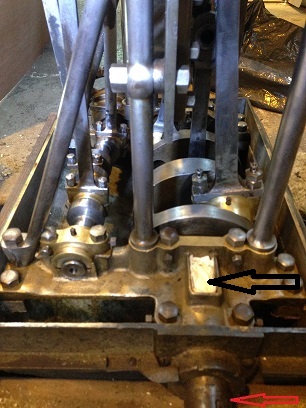

The engine was “wet lubricated” (my term) which means that it had oil in the bottom and the rotation of the engine caused oil to be splashed up into the area of moving parts. If you look at the red arrow in the picture above, you will see a small hole. These are in every rotating piece that needs lubrication and basically allows oil to drop into the bearings. Obviously, the bottom of the engine would have to be enclosed to keep the oil from giving the on-board steam engineer a hot oil bath! Some engines didn’t use the “splash” technique and had oil systems that included a reservoir with a small tube out the bottom that then dripped oil onto the rotating parts (sometimes into holes similar to the above).

In this engine, someone had put little wooden plugs (much like the end of a chopstick) into most of the lubrication holes. What a great idea that was! It helped keep out nastiness! Unfortunately, the engine had sat so long (after all, she was built in late 1890’s) that it wouldn’t turn. So, I pulled out all the plugs and squirted into the holes a little mystery oil over the period of a few weeks. Then I switched to chain saw oil which has a chemical that sticks to metal better. Lo and behold, after a few more weeks I got the engine to spin a little by putting a long bar across the flywheel connector on the crankshaft! The red arrow in the picture below shows where the flywheel attaches.

You can also see the little wooden pegs in the bearings. The white paper towel in the small square area just above the flywheel (at the black arrow) is a larger oil container that lubricated the large bearing under it. With continued lubricating and increasingly more rotating effort, I was finally able to get the engine to turn! Success!

While working to get the engine to rotate, I started the cleaning process. I had to be careful not to introduce any foreign objects like metal into the engine so I relied on liquid agents like carburetor cleaner and WD-40 to help clean. I also used 3M Black and Red pads to help with surface rust and dirt. The cleaning was difficult and time consuming with all the tiny areas of the engine. It would have been nice to steam clean the whole engine but that was not even possible since it would potentially harm the engine. So all cleaning was done by hand. But what a beautiful engine!

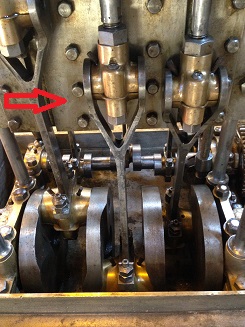

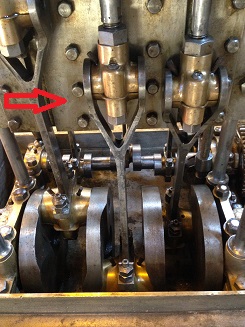

The following picture shows the bottom section of the engine after some cleaning. The red arrow shows the “knuckles” (my term) that connect the crankshaft journals to the pistons above (not in the picture). You can see how nicely the brass cleaned up!

Stay tuned for more news!